Using a computer-generated design, 3D printing, sometimes referred to as additive manufacturing, is a technique for building three-dimensional objects layer by layer. A 3D item is produced by the additive method of 3D printing, which involves building up layers of material. A final design is cut from a larger block of material in subtractive manufacturing techniques, which is the opposite of this. The result is minimal material waste due to 3D printing. As 3D printing has advanced, the number of businesses using the technology has grown quickly. The uses and applications differ amongst industries, but generally speaking, they include tooling aids, visual and functional prototypes, and even end-use parts.

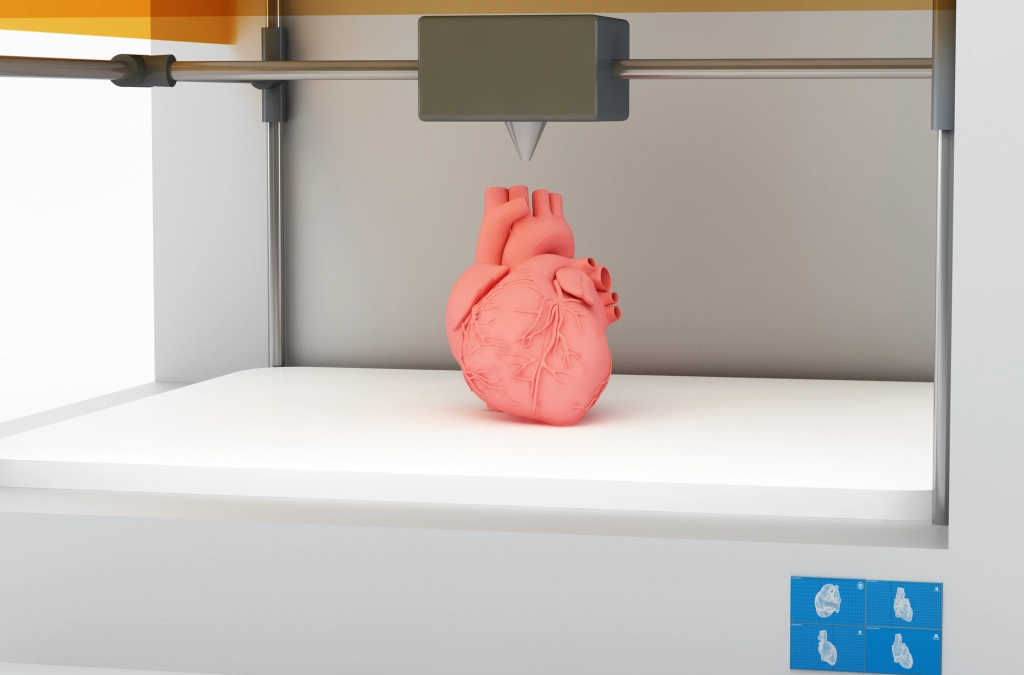

Prosthetics And Human Organs

The medical industry will undergo a transformation thanks to 3D printing thanks to improved materials and processes. Custom prosthetics and dental implants are already produced using 3D printing. We might even have the means to reproduce human organs in the not too distant future. An organ’s scaffold would be built using 3D printing, and then tissue would be grown using stem cells.

Biotechnological Implants

4D printing, which can be utilized for optics, pharmacological research, and the development of biosensors, is an evolution of 3D printing. Through the development of biomedical implants that can alter and vary their shapes to suit the environment around the organ, 4D may even result in the cure for rare diseases.

Pharmaceuticals

Incredible drug printing using 3D technology! Because machine cleaning is less complicated, new medicines may be produced in considerably less time. In the future, 3D printing might make it easier to produce medications locally as needed. This could have a significant effect on drug distribution and make it possible for local areas to quickly combat infectious diseases.

Emergency Action Mechanisms

Infrastructure for emergency response is one area where 3D printing will be very useful in the future. Buildings are being produced by startups employing 3D printing. In the future, it will be even more necessary to be able to quickly erect an emergency response facility or a mobile hospital in the event of a disaster.

Adaptable, Customized Clothing

Large amounts of waste from the clothes business are produced and landfilled. Imagine being able to have clothes made to our specifications on demand. With less waste, we would receive more of what we want. The use of 3D printing to address the housing crisis also fascinates me.

Custom-Fitted Products

The use of custom-fitted products will soon undergo a revolution in everything from seats to safety gear to apparel. Consider a motorcycle helmet that is molded to the form of your head to lessen impact damage. To increase safety, picture kid or adult vehicle seats that are specially made for them. Add it up for all other ergonomic products as well, such as apparel, eyewear, keyboards, mice, and even phones.

Educational Materials

The use of 3D printing in education can encourage student creativity and enhance learning and teamwork. It can deliver learning benefits that cannot be obtained in any other way by bringing things out of textbooks and off computer displays. Students could print 3D topographical models for geography lessons or 3D biological artifacts for scientific lessons, for instance.

Replacement Parts For Household Items

In the future, people will be able to utilize 3D printers to make spare parts for household items. Giving consumers control over the replacement parts market has a number of significant advantages. In the long run, it will save company owners money and time. It will also be simpler for customers to get the most out of their purchases, which will lead to an increase in satisfied clients.